WELCOME TO THERMO SCREED

THE NO 1 COMPANY ON THE SOUTH COAST

Floor datum survey provided on every underfloor heating project

A 50-year guarantee covers all our underfloor heating systems

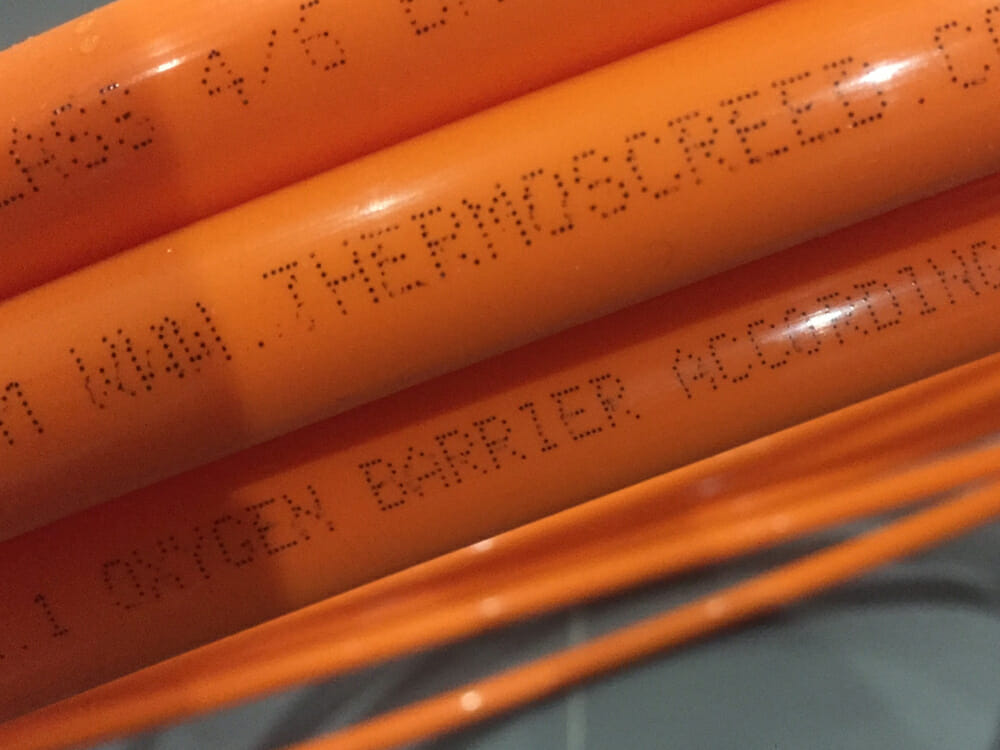

Thermoscreed is the South Coast’s No. 1 installer of underfloor heating and liquid screed. With an impeccable reputation, Thermoscreed will design and install your underfloor heating system to British Standards EN 1264, then pour a liquid screed over the heating pipes. We also specialise in the removal of surface laitance with dedicated sanding equipment. We provide a complete first fix underfloor heating and liquid screed package with one point of contact and responsibility.

Thermo Screed is are approved installer of Gypsol & Gyvlon flowing liquid screed. As a company, we pride ourselves on providing and installing the very best underfloor heating components. Every project is designed around our customers requirements. We install underfloor heating and screed for self-builders, professional builders, developers, and commercial customers. All of Thermoscreed’s work is undertaken to the highest standards, and carried out by professional, qualified, dedicated, friendly staff. All of our work is fully guaranteed.

Thermo Screed covers all areas of Hampshire, Dorset, Surrey, West Sussex, and Berkshire.

Future-proof your home with a premium Thermoscreed installation

We specialise in designing and installing underfloor heating systems for everyone. If you have a project in mind give please give us a call, we offer friendly advice and no obligation informative estimates,